The contact material is a bimetal consisted of a base metal – most often copper or its alloys – and built on the same level or above the level its contact material – usually a noble metal, silver or alloys thereof. Between the main and the contact material by special processing methods create such a metal connection that in subsequent processing of composite metal (bimetal) with bending, twisting, local profiling, cutting and others, it refers as massive metal. Adhesion between the base material and the contact relative to the geometric surface is between them is 80-100%.

The main advantages of contact Bimetals used in the production of electricity devices with low voltage can be expressed as follows:

- savings of scarce and expensive precious metal – silver, which is applied only on the surface or in isolated part of the volume of a specific piece;

- achieving a combination of the properties of the component metals or alloys (basic and contact);

- achieving new properties, which couldn’t be done with usage of monometals or alloys;

- provided in mounting phase of the production ready for usage contact nodes and in some cases avoid methods of soldering, welding or riveting.the contact bimetals produced by the original strain-diffusion technology is developed by the company without the use of solder materials and in the absence of protective gas, and other agents.

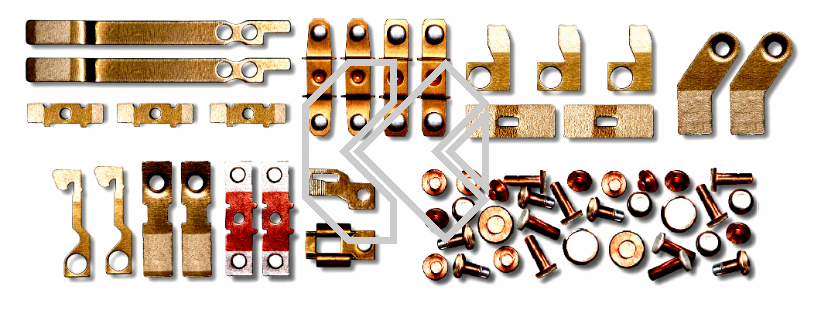

we have precise technological equipment and can supply contact bimetals in the form of tapes and articles (in a drawing from client).

Our enterprise produces contact materials based on copper and brass. Silver and silver-palladium alloys are used as a bar.